Users can dynamically interact with the toolpath, pinpointing exactly which line of code is being simulated. Multiple ‘Cross-Section Planes’ can be created to interrogate the resultant workpiece.

Once simulated, the workpiece can be measured in a variety of different styles – Arc; Thickness; Hole Centre Distance to name but few.

Critical dimensions and stock analysis can be generated through the Comparison tool.

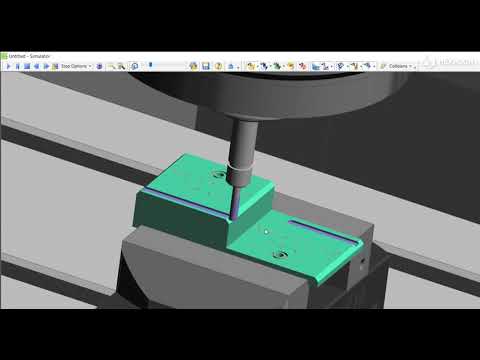

NCSIMUL Essential | EDGECAM 2022

Simulation for 3-Axis Milling parts can now be checked inside NCSIMUL Essential – a new component offered in EDGECAM 2022.0. The whole machining assembly including toolstore data is automatically loaded into NCSIMUL Essential where the .CL data is checked for potential gouges.

Users can dynamically interact with the toolpath, pinpointing exactly which line of code is being simulated. Multiple ‘Cross-Section Planes’ can be created to interrogate the resultant workpiece.

Once simulated, the workpiece can be measured in a variety of different styles – Arc; Thickness; Hole Centre Distance to name but few.

Critical dimensions and stock analysis can be generated through the Comparison tool.

Finish Groove Cycle | EDGECAM 2022

Turning customers will now discover extra functionality when using the ‘Break Corner’ command. Addressing specifically the first and last corners on a groove feature, formerly, the cycle did offer the ability to break the corners separately. EDGECAM 2022.0 now offers four settings – None; First; Last and Both. The new feature offers tighter toolpath control and prevents gouging when a groove is close to a neighbouring feature.

Simultaneous Five Axis Milling License | EDGECAM 2022

Customers who formerly possessed the Standard Five Axis Milling Licence (EN050-S) will now discover that the Advanced Five Axis Milling Cycle (EN050-A) has been automatically added to their configuration. This effect both 4-axis and 5-axis cycles.

As the name implies the Advanced cycle offers considerably more functionality and allows users greater toolpath control.

Machine Simulation TurnMill X Axis on spindle | EDGECAM 2022.0

EDGECAM 2022.0 now fully supports simulation of Turn_Mill CYB machine tool configuration with C axis on the spindle. Perfect code has always been supported but the machine simulation required enhancement as EDGECAM formerly displayed the tool moving towards the workpiece whereas, in fact, the workpiece actually moves towards the tool.

A simple switch within the code wizard parameters now assures both perfect code and realistic simulation.

Roughing Cycle - Performance Improvement | EDGECAM 2022

Reducing calculation time by enhancing EDGECAM’s Multi-threading processing capability, has led to a productivity boost when working with the Roughing Cycle in EDGECAM 2022. Regardless if you are machining wireframe or solid models, EDGECAM 2022.0 is producing toolpaths 2-3 times faster than previous versions.

Six Axis Machine Configuration | EDGECAM 2022

Reacting to the demands of the every changing machine tool builder world, EDGECAM 2022.0 now offer support for customer working with six axis machines tool.

Specifically, Horizontal machine tools with 2 programable axis in the ‘head’ can been synchronised with a rotary table

Simple 3+2 machining is supported as well complex 5-Axis simultaneous milling can be supported in all configurations.

Users will discover a new “Select Rotary Axes” command which intelligent allows the user to active the preferable axis to machine with.

Text Mill and Slot Cycles - Approach At Clearance added | EDGECAM 2022

Both the Text Mill and Slot Cycles now offer better toolpath control thanks to a new option - “Approach at Clearance”. As the new functionality can be found in all other milling cycles, it brings a more consistent feel to the commands.

Users no longer have to add extra CAM instructions to avoid potential toolpath collisions, the cycles will now guarantee that the toolpath initialises at a safe position.

Rough and Profile Cycles Through Limited Hole Feature | EDGECAM 2022.0

When machining a “Limited Through Hole Feature” EDGECAM 2022.0 will now allow you to cut below the Feature depth. Formerly, the toolpath stopped precisely at the Feature depth which in certain instances would cause the toolpath not to fully break through the feature.

Users may now specify a negative depth value to guarantee the toolpath fully passes the feature but, the software is sophisticated enough to clamp the toolpath depth to avoid accidently cutting into the other side of the part.

https://www.edgecam.com/

Roughing Cycle Minimum Helix control | EDGECAM 2022.0

EDGECAM 2022.0 introduces new functionality allowing users to exert tighter toolpath control and reduce cycle time. Specifically when using the Helix approach type strategy, a user can now specify the Minimum Helix value for the toolpath.

Without this control, the toolpath could sometimes, revert to a Ramp approach strategy where not only cycle time could be increased but tool life may be shortened.

https://www.edgecam.com/