EDGECAM Waveform Roughing Features at Design & Manufacturing South in Orlando

Silverhawk Solutions will be showing computer simulations of EDGECAM’s revolutionary waveform roughing strategy at the Design and Manufacturing South Exhibition in Orlando. Manufacturers say waveform pushes the boundaries of traditional milling.

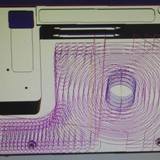

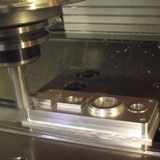

EDGECAM reseller Silverhawk, will be showing how waveform maximises material removal rates while prolonging both tool and machine tool life. It produces rough milling toolpaths that deliver shorter cycle times, greater tool life, better surface finish, and are kinder to machine tools.

Waveform creates its toolpaths so that when viewed from above the distance between the roughing passes – also known as stepover – varies, but this variation allows the actual width of cut to stay the same and at the optimum level, meaning the spikes are removed. Chip load stays constant, and the depth of cut employs the cutter’s entire flute length.

Silverhawk’s waveform simulations will be shown on computer screens at booth #626.

Domenic Lanzillotta, EDGECAM’s Channel Manager, Americas Region, says: “Waveform roughing is all about gaining the confidence to accept a whole new way of thinking. Because it’s going outside the normal boundaries of what has been achievable and realistic in the past, customers are doing waveform roughing with normal feeds and speeds to begin with, then they start to realise its enormous potential, and ramp up the speed and feed rates. And that plays a major role in increasing profitability.”

Design & Manufacturing South is a major exhibition of cutting edge technologies, held at the Orange County Convention Centre, in Orlando, Florida, on March 6 and 7.

Silverhawk: Booth #626.