EDGECAM 3D Software Features in Factory Visits

Visitors to a major manufacturing company in Germany are shown how 3D EDGECAM software has improved the production process of high-precision parts.

With a multi-billion Euro annual turnover and 120 sites in 25 countries, ZF Friedrichshafen AG are a significant supplier to domestic, commercial, construction and agricultural vehicle manufacturers around the world. They make a range of components such as transmission systems, axles, shafts and housings for customers including Caterpillar, Claas, John Deere, CNH and AGCO.

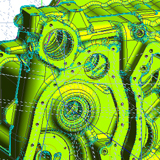

Production services team manager in the location of Passau (for 12 A-division-plants), Peter Robl, demonstrates to customers about the part EDGECAM plays in the process of manufacturing their parts, when they visit ZF factories. “We discuss our performance in the 3D CAM field, so customers are fully aware that EDGECAM has enabled us to move on from the old traditional way of working with 2D drawings, to 3D models. It’s important they know that we now work in a 3D and virtual area, and that our computer integrated manufacturing means their components are produced to the highest quality.

“EDGECAM was the only system that delivered the process automation tools we demanded during our evaluation of 10 CAM solutions. The degree of integration and interoperability we achieve between EDGECAM and our corporate CAD solution, Pro/Engineer, enables us to take component designs and automatically generate and apply optimised tool paths.” He says the fact that the EDGECAM product team have a good understanding of the problems and issues facing ZF’s intensive manufacturing process, has developed and speeded up their NC programming.

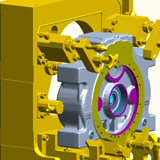

In addition, he also dedicates considerable time in explaining to ZF’s own programmers and machine operators about the role EDGECAM plays in their overall NC process chain. “Our staff need to know about the process for our NC simulation and Product Data Management (PDM) system, so I always explain about our big investment in post processing to the control systems and machines. We’ve installed an excellent I.T. infrastructure with NC management system - FATool and EDGECAM for NC programming. I demonstrate how the processes work between one system to another, and how we’re going forward with the functionality between FATool and EDGECAM, and between EDGECAM and the CNC machines.”

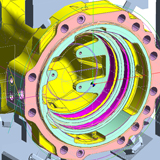

With ZF having a total of 84 users working on 52 seats of EDGECAM, the software drives more than 400 CNC machines across manufacturing plants – mainly 3- or 4-axis milling centres and lathes with 2 spindles and 2 turrets from a number of different manufacturers. Also 5-axis and turning-milling machines are programmed by EDGECAM. Production services engineer Johannes Fuerst says it is absolutely vital for the smooth running of their factories that EDGECAM can run different manufacturers’ machine across a range of cutting technologies.

ZF’s EDGECAM modules include Ultimate Milling and Ultimate Turning, Solid Machinist, Strategy Manager, Solid CAD/CAM, 5-axis Simultaneous Milling and NC Simulation, ensuring they are able to machine top quality, high precision parts at six manufacturing plants in Germany, Austria, the Czech Republic and Slovakia. They have generated around 2200 EDGECAM programs in total, many of them using more than 100 tools, and with over 1,000 instructions.

Before EDGECAM, production planners had to use 2D drawings because their previous 2D CAM system could not process 3D CAD data. Now they can directly load the Pro/Engineer CAD models using Solid Machinist. EDGECAM also gives planners additional options for rationalising every individual processing step, and because of its full associativity with the CAD model, 100 % error-free data transfer is assured.

“EDGECAM is an absolutely vital and fundamental part of our manufacturing process. In the past we worked with 2D drawings and a manual text editor with also using a postprocessor (UNC8500i) , but with EDGECAM we use the 3D solid geometry from the design department. It’s so much easier to prevent errors and produce the parts with absolute accuracy.”

And for his colleague, Max Weishaeupl, the simulation feature is of paramount importance. “With the user being able to simulate how the part, the fixture, the tool and the machine will all combine to carry out the programming before the actual production run, gives us absolute confidence to press the button to start the manufacturing process, knowing we’ve created safe, to 99.9% collision-free CNC programs.”

The EDGECAM postprocessor, which he wrote, is also very important for the complete process. Many things, like syntax check for the controller, proofing the limits in the workingroom, output cycles for this machine and longhand for the other machine, helps to avoid machine errors. The compatibility for the posts is absolutely necessary for the inhouse process, because a considerable amount is changed on different machines in the production.

Product variation means about 600 setups are needed daily, with changes of workpieces, tools, equipment and NC programs. EDGECAM enables this logistical challenge to be met with speed and accuracy, ensuring the efficient machining often of just-in-time batches comprising between 1 and 250 units.

Because Max Weishaeupl has been with ZF for around 30 years, starting as a machine operator, he had extensive experience of working with their previous 2D system, and says that moving to 3D with EDGECAM has developed the manufacturing processes by increasing productivity and efficiency.

However, Johannes Fuerst has only known EDGECAM, and it was as a direct result of working with the software that led to him making a career change from CAD to CAM. “I had intended to work in ZF’s design department creating models of gear boxes and other high precision components on Pro/Engineer, but came across the CAM-Process during my first internship.” He went on to complete his diploma featuring EDGECAM, before starting in the production services department, working with Max Weishaeupl on training and supporting staff in its use.

He is pleased that EDGECAM is a long-term investment for ZF, adding that the support service is an important part of the close working relationship with EDGECAM and its parent company, Planit Software. “Having direct access to the online support portal means we get answers to our queries in a very short time. The support team know exactly what we need and how to achieve it. We get a response within an hour, and very often we get the solution within that time, too.”

ZF’s day to day EDGECAM requirements are managed by the software’s reseller in Germany, Cipro, who were also instrumental in its implementation and assisting in processes, along with user training. Managing director Manfred Kukla, and chief technical officer Martin Biewer are in regular contact with Johannes Fuerst and Max Weishaeupl to define their ever-changing needs, and then work closely with them to provide a good solution which achieves their objectives. “For example, we’re currently developing a new tool with ZF to improve the efficiency with which EDGECAM receives information from their CAD system,” says Manfred Kukla.

Peter Robl is also impressed with the way EDGECAM keeps itself abreast of technical changes in other parts of the manufacturing process, so the software is capable of operating with new products as soon as they are launched.

As an example he cites the extensive work EDGECAM has done to ensure the seamless introduction with Creo Elements/Pro – formerly Pro/Engineer, from PTC. He had been concerned about the new Creo vision announced towards the end of 2010, which Creo acknowledged could cause “some confusion” and raise a number of questions about what the changes would mean to the software that companies relied on every day.

Nick Spurrett says: “We understand that it’s absolutely paramount to ZF’s business – and to many of our other customers – for EDGECAM to work with PTC, whatever changes they may make to the products. As soon as it became known that changes were being made to Pro/Engineer we took the initiative to ensure that EDGECAM would be instantly compatible.” He adds that it is just one example of how EDGECAM and Cipro are working successfully with ZF to assist them in getting the very best from CAM software at their plants around the world.